About us

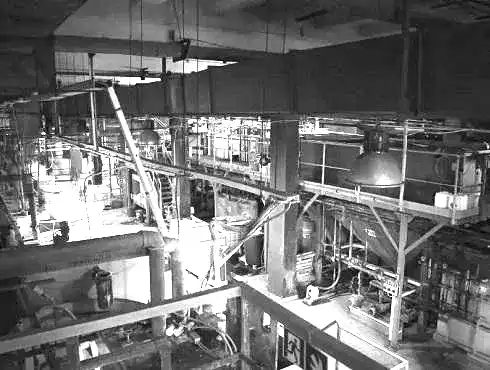

We are a leading supplier of electroplating services.

The greatest advantage of our company is a team of qualified and ambitious employees with an innovative attitude to the plating industry in accordance with the Integrated Management System. We have IATF 16949, ISO 9001, ISO 14001 and ISO 45001 certificates.

Thanks to modern technologies and advanced machines, we provide services of the highest quality. Our specialty is galvanic treatment of steel, ABS plastics and non-ferrous metals.

Our services include:

Multilayer coatings:

- copper-silver

- copper-tin

- copper-nickel

- nickel-silver

- nickel-tin

- copper-nickel

- nickel-copper

decorative galvanic coatings on plastic ABS (metallization ABS/chrome plating ABS):

- nickel-copper-nickel-chrome

additionally, we offer a wide range of surface finishing in order to obtain the expected appearance and corrosion resistance:

- zinc coatings with additional chromating (passivation) in the colors: transparent, blue and black without Cr +6,

- zinc-nickel coatings with additional chromating (passivation) in the colors: transparent and black without Cr +6,

- zinc and nickel zinc coatings with sealants and waxes

- copper, tin, nickel and silver coatings with matt or glossy finish

- ABS coatings with glossy, satin and satin-pearl finishes.

Our mission

Galwanizer’s vision is to become a globally recognized company offering unique surface treatment solutions. Our goal is to develop modern technologies that improve quality and efficiency while minimizing the impact on the natural environment. We want to be a trusted partner for customers who value innovation, reliability and an ethical approach to business.

Our mission is to provide surface treatment services using advanced technologies and innovative solutions. We meet customer expectations by taking care of quality, efficiency and sustainable development.

Continuous development and international expansion.

We strive for continuous development and expansion into international markets, maintaining local values and understanding the needs of customers around the world.

Continuous development and international expansion.

We are constantly looking for new technologies and solutions to improve the quality of our services and set new standards in the surface treatment industry.

Long-term relationships based on trust.

We build long-term, trust-based relationships with customers, suppliers, employees and the environment, striving for mutual success and satisfaction.

Quality and perfection.

Our priority is to provide services of consistent quality that meet customer expectations, taking into account industry standards and safety requirements, while striving for perfection in every aspect of our business.

Responsibility and ethics.

We are responsible for our actions towards customers, suppliers, employees, the surroundings and the environment. We focus on an ethical approach to business, complying with all legal regulations and industry standards.

Efficiency and profitability.

We are constantly improving our production and organizational processes to maximize the use of resources, increasing the efficiency and profitability of our operations while maintaining quality.

Respect for the natural environment.

We operate with respect for the natural environment, implementing green technologies and minimizing the impact on the planet, striving to eliminate hazardous materials and galvanic waste.

Respect and honesty.

We treat all stakeholders with respect and honesty – from employees, through customers, business partners, to every stakeholder, creating an organizational culture based on cooperation and mutual understanding.

Customers (industry sectors):

automotive

construction

sanitary fittings

electro technical and energy industry

household appliances industry

The Galwanizer company for many years has been cooperating with suppliers who meet the REACH assumptions.

- lead

- mercury

- cadmium

- chrome +6

The integrated permit was introduced in the European Union countries by the Council Directive (IPPC Directive – Integrated Pollution Prevention and Control), as a formal and legal instrument. Galwanizer received the Integrated Permit on April 30, 2007, with maximum limits for individual impacts:

- discharging sewage into water or soil,

- production of waste,

- introducing gases or dust into the air,

- emitting electromagnetic fields,

- noise emission.

The company is meeting also requirements of directives:

- 89/391/EWG with the objective to introduce measures to encourage improvements in the safety and health of workers at work

- 89/654/EWG concerning the minimum requirements in the field health and safety at work

- 92/58/EWG specifying the requirements for signs and safety signals

- 95/63/EWG specifying health and safety requirements for the use of machines and other technical devices by employees

- 98/24/WE concerning the safety of employees and protection of their health against the risks related to chemical at work

- 89/656/EWG determining requirements of the safety and hygiene of the work concerning using by workers centres of the individual protection

- 90/269 concerning requirements of the safety and hygiene of the work at the manual transport

If you have a question ask it and we will try to answer!