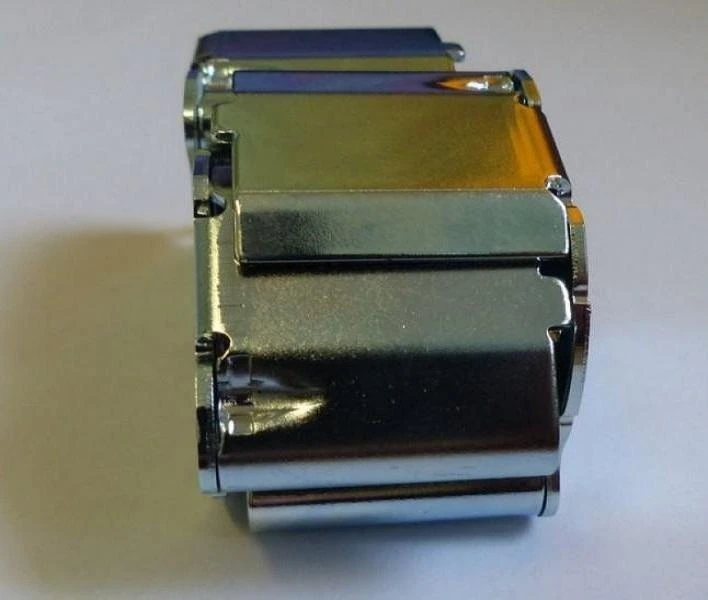

Zinc plating

Zinc plating is realized in modern, fully automated suspension and drum technological lines, in a stable manner, organized in accordance with the implemented IATF 16949 Management System, constantly supervised by competent personnel.

The obtained zinc coatings guarantee high corrosion resistance. The advantages of zinc coatings include an excellent thickness distribution and an aesthetic appearance. We offer a wide range of preparations for finishing zinc coatings:

- transparent, blue, black and thick layer passivations Cr+6 free.

- Sealants,

- Waxes.

The technologist is responsible for the quality of the received products. To this purpose, he has to his disposal a well-equipped analytical laboratory and a control and measurement laboratory, where:

- measurement of thickness is carried out through Roentgen radiation (X-Ray)

- corrosive resistance is measured in a salt chamber (with accordance to the ISO 9227).

We guarantee full supervision of identification and traceability of the entrusted products. Over the recent years we have guaranteed our Clients a compliance of our deliveries at the level of 99.9% (as regards required amount, quality, assortment, deadline and the way the products are places on pallets).

The technological process is fully automatic and supervised:

- selection of the parameters of the process is carried out by the operator who chooses them from the database

- it is possible to adjust all the parameters of the process in order to achieve optimal conditions of the process for each element

- the process is stabilized – supplementing materials, e.g. polishing materials, pH correction, are carried out in an automatic manner.

Zinc plating – environmental safe

The technologies that are used were devised so as to protect the environment: they do not include cyanides and complexive additives or Cr+6.

We use proven preparations of companies leading on the market.

The zinc layers we produce are made mainly for the following industries:

- Automotive (80%)

- Construction (15%)

- Energy (3%)

- Telecommunication (2%)

Our coatings are comply with the internal norms of our Clients. They match the requirements of standards such as: VW, Volvo, and Mann.

We also encourage you to check out our zinc-nickel offer.

See the full offer

Zinc plating

Zinc – nikiel

Chrome plating on ABS

Silver plating

Nickel plating

Copper plating

Tin plating

Other

If you have a question ask it and we will try to answer!